Results:

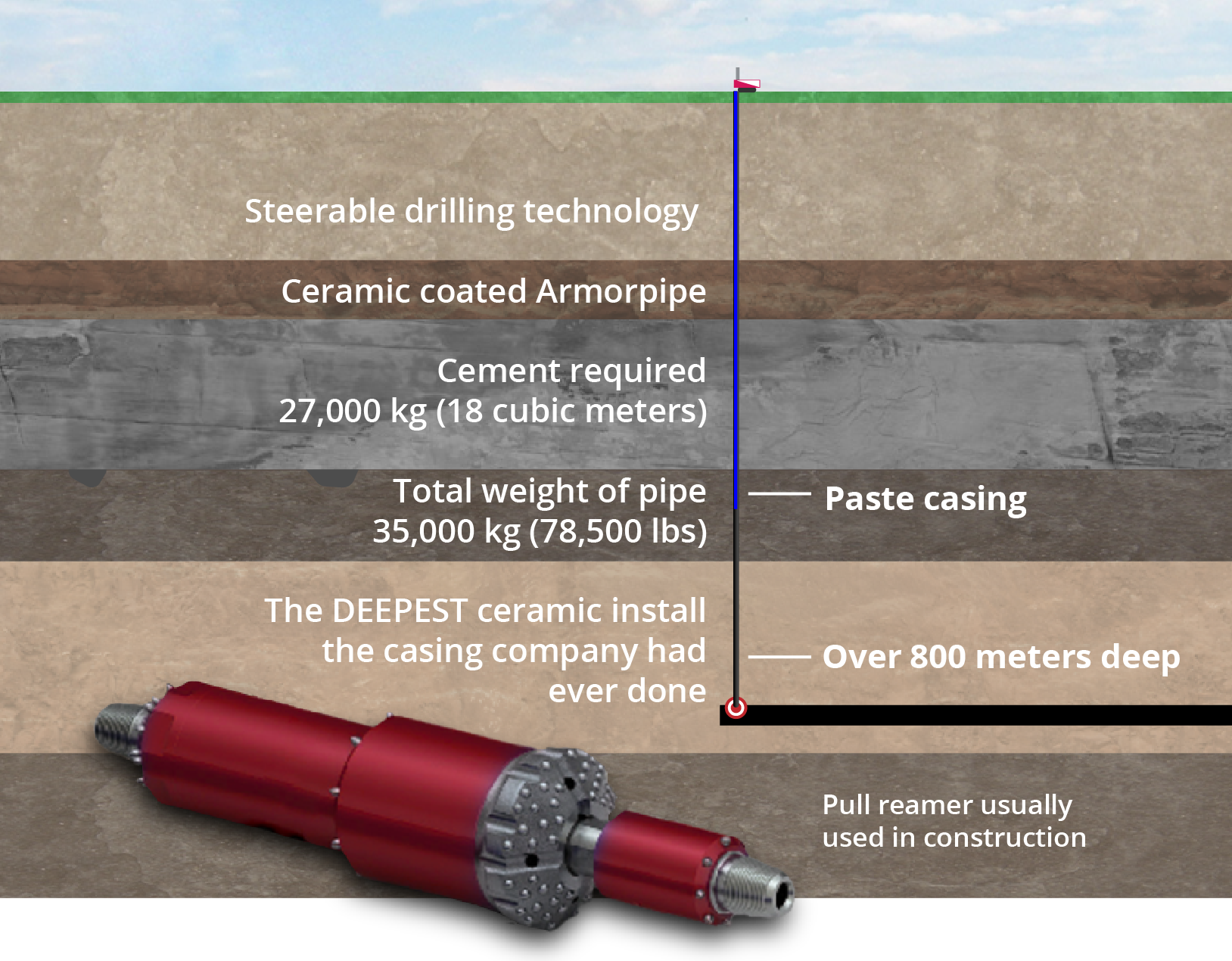

Our innovative team used real-time hole survey data normally used in oil fields to monitor the pilot hole drilling process. Using down hole steerable drilling motors, we were able to make the course corrections necessary to have precision accuracy in hitting our target. A pull-reamer (normally used in the construction industry for horizontal drilling) was installed underground and then utilized to enlarge the hole in a back-reaming pass.

Next paste casing made of ceramic coated armorpipe was installed. The entire casing weighed in at over 35,600 kg (78,500 lbs) and required 27,000 kg (18 cubic meters) or cement. It was the deepest ceramic install the casing company had ever done.

In the end our team at Major Drilling was able to use their creative problem solving skills to complete the job. Where others may have found problems, Major Drilling found solutions.