Pictured is the Major Drilling EF-100 drill used at the record-breaking 3,467-meter Discovery 1 deep drill hole, now the longest diamond drill hole in Canada, at Osisko Mining’s Windfall Project site in Québec.

Major Drilling is receiving worldwide attention for its record-breaking diamond drill hole—now the longest in Canada—at 3,467 meters. On January 26, 2020, Major Drilling broke the record at the Osisko Mining Discovery 1 hole at the Windfall Lake gold deposit in Québec. Just 15 days later, the project achieved another breakthrough when the Osisko team and drill partners reached the 1 million meters drilled milestone at Windfall.

Major Drilling is receiving worldwide attention for its record-breaking diamond drill hole—now the longest in Canada—at 3,467 meters. On January 26, 2020, Major Drilling broke the record at the Osisko Mining Discovery 1 hole at the Windfall Lake gold deposit in Québec. Just 15 days later, the project achieved another breakthrough when the Osisko team and drill partners reached the 1 million meters drilled milestone at Windfall.

The triumph of the longest diamond drill hole in Canada is an indicator of the quality of partnership between Osisko Mining Inc. and Major Drilling. “Discovery 1 is a great success and achievement,” Osisko President and Chief Executive Officer, John Burzynski, said. “We are very proud of our Osisko team and Major Drilling for their tremendous work completing this hole.”

Osisko is a mineral exploration company focused on the acquisition, exploration, and development of precious metal resource properties in Canada. Osisko trusts Major Drilling on its projects knowing teams will complete every task with the core values of quality, safety, and results top of mind.

Behind the Scenes Q & A

Kevin Buttimer, Major Drilling Canada Assistant Coring Manager

Richard Aube, Major Drilling Canada Operations Manager

How is such a remarkable accomplishment like Discovery 1 achieved? Major Drilling Canada’s Kevin Buttimer, Assistant Coring Manager, and Richard Aube, Operations Manager on the Discovery 1 project, explain:

Q. What was the scope of the project?

KB: In 2018, we were asked to bid on a project that promised to be potentially historic. Our price vs. cost per meter method was a compelling reason Osisko took a hard look at how Major Drilling could bring value to this really significant project.

Q. When the project began, Osisko CEO, John Burzynski, said, “We remain convinced that as we continue deep exploration, Windfall will grow to join the ranks of world class high-grade and long-life underground mines in the Canadian Archean.” How did Major Drilling help Osisko see its convictions through to results?

Core is pictured from the 1-million-meter drilling milestone at Osisko Mining’s Windfall Project. Image courtesy of Osisko Mining.

KB: Simple in theory, but much more difficult in practice. However, having a determined client, a dedicated team of ops personnel, reliable equipment, and an experienced support staff helped to successfully and safely complete the hole.

Q. Explain about preparations for this project, the rig used and how you reduced the possibility of downtime.

KB: We moved our EF-100 deep drill rig from Red Lake, Ontario, to Windfall, in early May 2019. From the onset, this drill was destined to become the machine to drill the longest diamond drill hole in Canada. Osisko requested it during initial discussions at the Major Drilling Corporate Head Office in 2018. There was some prep work to ensure that the rig, tower, wireline hoist, comb, and other major components could handle the rigors of drilling such a hole. In addition, it was suggested by Richard Aube and agreed by Osisko that a cement pad be poured to help with stability and cleanliness.

The initial hole (OSK-W-19-1944) began May 10, 2019 at -56-degree angle. We drilled to 812 meters, but the hole deviated too much, and we had to restart.

Q. Deviation on long holes can be a huge challenge for drillers. How did the Major Drilling teams adjust?

RA: We’re used to these types of obstacles. The adjustments really taught the Osisko team more about the geology and gave everyone a better picture of what to do when we restarted. The client decided that hole should start at -51-degree angle.

Q. Who was on your team and how did they innovate and adjust to conditions?

RA: We had an excellent team of experienced Major Drilling people on this high-profile and very demanding project. Joining me were foremen Normand Bordeleau, Martin Labreche, Gabi Routhier, and Sylvain Guay-Bedard; drillers Adam Senow, Christian Rheault, and Kenneth Philbert; and drill assistants Steven Leclerc, Anthony Berneche, and Daulton Clement.

On May 30, 2019, we restarted from the collar (OSK-W-19-1970) at -51 degrees, then drilled to 3,467 meters. The hole ended at -28 degrees. At first there was a lot of concern that-51 degrees was too flat an angle to drill a long/deep hole. Some of our experienced team members assumed that the hole would have started between -75-85 degrees. That’s what makes this hole so unique. We worked with the client’s desire to start flat, so we used our knowledge, the power of the drill, and the right equipment to make it to the desired depth.

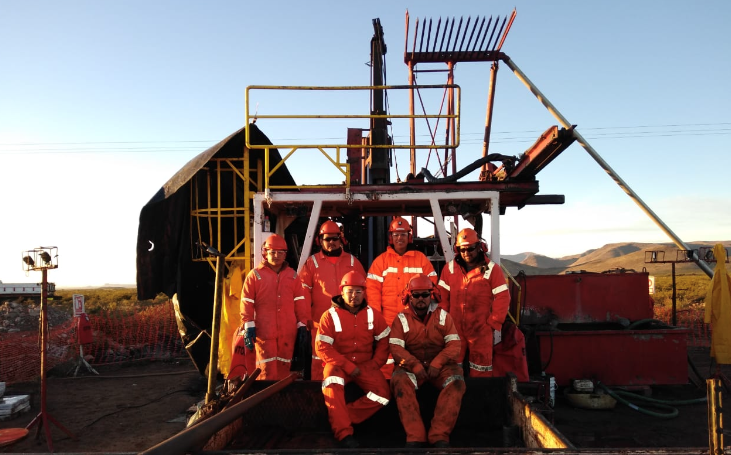

Celebrating the historic longest diamond drill hole in Canada is the Major Drilling team standing, left to right, Martin Labreche, Christian Rheault, Richard Aube, Adam Senow, and Gabriel Routhier. Kneeling, left to right, are Steven Leclerc and Anthony Berneche. Other team members missing from this photo are Sylvain Guay-Bedard, Normand Bordeleau, Kenneth Philbert, and Daulton Clement.

Q. What equipment helped you get the job done?

RA: Osisko geologists and staff were on-site and watchful. They trusted us to use our experience to bring in the equipment, people, and gear needed to get the results they wanted. We used the EF-100 deep drill, a machine that we have used at other special projects but none to the desired depth of Discovery 1. There were, of course, nerves and many discussions with various parties to ensure that we had the best plan in place.

Joining the Major Drilling team in this photo is Osisko Mining geologist Isabelle Roy (standing, far right).

Q. Can you elaborate on the depth of casing, size of rods, and any special challenges that you would like to mention?

RA: The hole had HWT casing to a depth of 509 meters. NRQ rods were used to drill the majority of the hole to 3,143 meters. The hole was completed at 3,467 meters with BRQ rods.

I would like to mention that during the course of the hole, there were 11 Clapeson wedges set to keep the hole on the client’s desired trajectory.

Q. What makes the Discovery 1 hole so unique beyond its prodigious depth?

RA: A couple of things here. First, the flat starting angle. No one that I spoke with in the diamond drilling industry, some with decades of experience, had ever heard of attempting a hole at such a flat angle. However, we knew that the EF-100 had the power to complete the hole even though it was never used to these depths before.

Q. What was the reaction of the Osisko and Major Drilling teams when that final meter was drilled?

RA: Our guys were absolutely thrilled. We worked really hard to get this project done and do what it takes to make our client happy with the results. Everyone at Major Drilling is deservedly proud of our guys. When we finished, the team asked, “Where is the next special project?” Clearly, they’re ready for the next challenge.

Q. What role did safety play in the success of the Discovery 1 hole?

RA: Of course, safety is our top priority. From PPE to equipment checks, we were always thinking about avoiding risks and using the tools we have that keep our drillers and the work they do safe. The TAKE 5 program to assess risk was used faithfully, along with daily check-ins by the foreman, inspections, daily toolbox meetings, safety blitzes, etc.

More Record Success

Achieving impressive drilling records isn’t new to Major Drilling. Other records on the books include projects operated by Major Drilling Mexico and a previous company diamond drilling record for Major Drilling Canada.

The Major Drilling Mexico team that achieved the branch’s deepest NQ diameter hole in Mexico poses with core drilling equipment on site at the Bismark Mine in Chihuahua.

In late 2019, Major Drilling Mexico announced it reached its deepest NQ diameter hole at just over 1,985 meters at the Bismark Mine in Chihuahua, Mexico. The team is proud of their drilling accomplishment, a true milestone for drilling operations in the region. Also gratifying is the positive partnership with Industrias Peñoles which wholly owns Bismark Mine, one of Mexico’s largest zinc mines, in operation since 1992.

A previous diamond drilling record occurred in 2008 when Major Drilling achieved a record-breaking depth of more than 3,400 meters at Red Lake, Ontario, Canada. The new record at Windfall is a testament to Major Drilling’s ongoing efforts to achieve the best possible results for its clients.

Throughout its 40-year history, Major Drilling has positioned itself as one of the largest specialized drilling operators in the world by leveraging its skilled personnel, specialized equipment and robust safety systems.

“It is an honor to have been a part of this monumental project,” Major Drilling President and Chief Executive Officer, Denis Larocque said. “We are proud of the hard work and expertise that our team has contributed along with Osisko Mining to reach this historic milestone in Canadian drilling.”

Achieving the record longest diamond drill hole in Canada was a great way to kick off Major Drilling’s 40th anniversary. In 2020, Major Drilling Group International Inc. reflects on four decades of expansion and drilling specialization and will continue investment in equipment, people and services to ensure the quality, safety, and results clients expect.

Follow Major Drilling on LinkedIn, Twitter, Facebook and Instagram to receive the latest company news and updates.

Learn how to get your premier drilling program started with Major Drilling by contacting Corporate Business Development Manager, Kevin Slemko, today.

Four of the Major Drilling Canada team members responsible for drilling just over 3,400-meters in 2008 are pictured at the drill site in Red Lake, Ontario, Canada.

Major Drilling Canada’s Kevin Buttimer (far left) accepts the Safe Day Everyday Gold Award at the AME Roundup awards event in Vancouver, B.C. Also pictured are (l-r) Bill Mercer, Chair, PDAC Health & Safety Committee; Candice Wingerter, Senior Health, Safety and Environment Advisor, Growth & Innovation, Rio Tinto Exploration Canada Inc.; and Kim Bilquist, Chair, AME Environment, Health & Safety Committee. Photo Credit: AME