Heath Cazier, Major Drilling America Drill Supervisor, shows a core sample inside an HQ-size bit used during surface drilling.

It’s dark when a cell phone rings inside the red and white drill shack set up 90 kilometers (56 miles) south of Long Canyon, Nevada, USA. Heath Cazier answers with his first “hello” of the day and wraps the call with “absolutely.” He is ready for anything.

The day’s adventures are already underway. Together with his crew, the high-performing, dynamic supervisor collects core samples for the client, keeps the drill turning, and leads with safety in mind every step of the way. “There’s an excitement to being needed on the team,” he says.

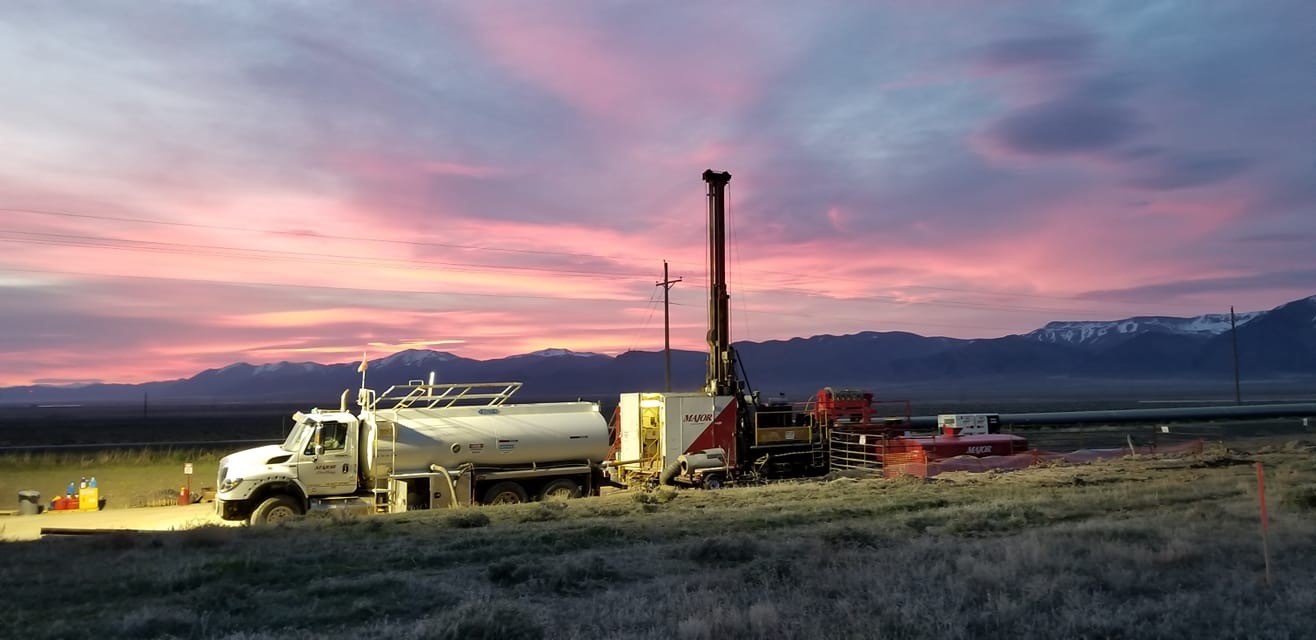

Cazier (pronounced cuh-ZAYRE) checks his team’s gear, water bottles and PPE, complete with face masks to protect against COVID-19, for a day of “putting the rock in the box.” Cool temperatures in the high mountain desert will quickly rise to 38 degrees (100 F). Cazier steps out of the shack as the growing light of the morning sky outlines the 10-meter (33-foot) mast of the LF-90 core rig.

The mast of the Major LF-90 surface drilling rig is silhouetted in the early morning sky at the New Placer Dome Cortez Mine, approximately 113 kilometers (70 miles) southwest of Elko, Nevada.

A driller and an assistant join Cazier, and together they mark safety checklists making the cross-shift transition with the previous crew complete. The sun creeps over the horizon as the fresh crew settles into drilling for the next 12 hours on New Placer Dome’s Kinsley project, a gold exploration project in the vicinity of the producing Long Canyon mine owned by Newmont Goldcorp.

Life of a Driller

The day is busy, and Cazier doesn’t have much time in the middle of his 20-days-on schedule to think about his next 10 days off. Work includes hauling rods, packing gel, loading core boxes, breaking down rigs and moving rigs. Each drill set up is unique and customized to the client’s needs.

Factors like client requirements, ground conditions and weather determine the pace. At Long Canyon, 300-foot drilling shifts are common, with cycles of emptying core tubes into sample boxes, mixing mud and swapping out tubes taking less than six minutes.

Cazier gets “rocks in the box” at a project site in Nevada, USA.

Cazier says on some projects, his team will pull four tubes a day while others pull a brisk 42 tubes per day. “I prefer it fast paced. It’s way easier because when you are drilling the bigger shifts, everything flows,” he says. To Cazier, good workflow is important—just as the stream of good money, a job that keeps his body in shape, and opportunities to mentor others are important.

When he does take days off, Cazier will return to southern Idaho, about 800 kilometers (500 miles) northeast, to join his wife and two teenage sons. It is a great improvement over his early days of drilling at Long Canyon when he was once on a job for 89 concurrent days.

He shares that memory in a way that many long-time drillers do—inconspicuously–showing, rather than telling, how extensive his surface core drilling experience really is. Yet, when asked about his expertise, he simply states, “I’m just a guy who’s out there looking at the sun when it’s out.” He’s a surface driller to the core.

Days “looking at the sun” have added up to excellent results for a variety of projects at which Cazier drills for Major Drilling clients in Idaho, Nevada and Arizona. That, combined with staunch dedication to safety, makes for a satisfying life in the field.

What he likes most about his job is that each day is distinct. “You can lie in bed in the morning and have a game plan, and as soon as you get to the job, it may all be different,” he says. That has its benefits because it makes the days go by fast. “As a supervisor, I’m scheduled for 12 to 16-hour days where it’s phone calls, emails, guys calling me, and watching over the job to help the drillers and assistants perform and improve.”

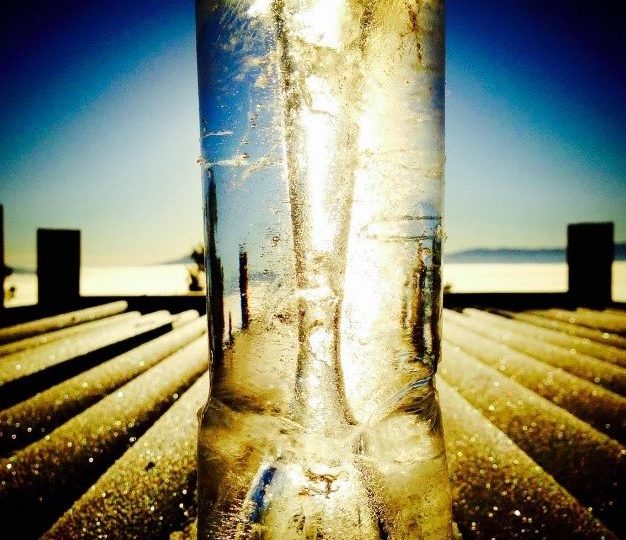

Cazier’s days of “looking at the sun” as a surface driller come with moments of beauty. He captured this shot of the sun shining through any icy formation attached to a three-inch water line—a prism amongst rows of frosted, sparkling drill rods used one crisp January morning in 2013 at the Long Canyon project.

Drilling—A Multi-sport Event

At 6 feet, 2 inches tall and a powerful 195 pounds, Cazier thanks his past as a cattle ranch hand and a collegiate-level athlete for the work ethic he brings to each drilling project. As a teen living in rural, southern Idaho, he got a “big break” when he was spotted at the 1996 USA Track and Field Junior Nationals – an Olympic-qualifying event. After a strong finish, a coach recruited him to join the Boise State University track and field team where he competed in the decathlon for three seasons. In those days, Cazier would train six hours and study another six, building his adaptability, athleticism and determination.

Cazier says the all-around skills needed for a decathlon—a two-day series of sprints, jumps, hurdles, vaults and throws—are like the skills found in a top driller. “You can’t just be good at one thing,” he says. “To be good at drilling, you have to be diverse in multiple things.”

In the shadows of the Teton Range, Heath Cazier learned to work outdoors doing ranch work like bucking hay, moving cattle and fixing fences.

An upbringing of summers working on his grandfather’s cattle ranch in Idaho helped too. The parlance of the region is friendly and casual, leading Cazier to often add the phrase “pretty much” to his accounts.

“My work ethic pretty much started from my step-dad who was always gone working, and I saw the sacrifices. I learned the satisfaction that comes from working all day doing things like bucking hay, moving cattle, fixing fences and the joy that came from how it was never the same thing every day.” He later spent time working as a retail manager and as the head of his own construction projects.

A self-proclaimed “surface guy,” Cazier joined Major Drilling in 2008 as a drill assistant helping on an LF-140 rig in Long Canyon. He made a life-changing decision to leave his job in construction to join a coworker whose cousin worked for Major Drilling. Cazier filled out an online application, went to training class with his buddies, and they received assignments. One friend went to New Mexico, and he and the others went to Long Canyon. “We didn’t know anything about drilling, but we kept on and stuck with it,” he says.

A typical helper might be in that position for one to seven drilling seasons before moving into a driller role. For Cazier, that promotion came much faster.

“When I started out as a helper, it lasted just eight months,” Cazier says. When he returned the next season, the project was short a driller, and the supervisor asked him to train right away so he could quickly step into the role. “At first it was scary being in charge, but I had a night shift manager for a week show me everything, so it worked out.”

Heath Cazier is an ambassador for safety in this social media campaign graphic. He reinforces how the TAKE 5 risk assessment helps drillers think through every task they do.

He later worked jobs using the Major 50, then the EF-75 when the rigs were first brought to the U.S. from Canada. As his experience grew, he worked LF-230 and LF-90 diamond core drilling rigs. His career surged ahead, and Cazier became a supervisor, leading him to visit and supervise at many different projects and locations in the western U.S.

Management and Safety

“Everyone wants to be on Heath’s crews,” Shaun Fleming, Major Drilling America Drilling Operations Manager, said. “He manages to complete the work with the highest quality of service and performance for clients. He’s also a great mentor for the less experienced drillers, helping them meet every challenge.”

As a trained athlete, putting in the work just makes sense to Cazier. “If I’m asked to do something, I make it happen,” he says. He enjoys the benefit of experience and has built a crew he enjoys and who he knows can get the work done. “I feel like I can get the results, and I can guide my guys to do what we need to achieve.”

He sees returns on the mentoring and training as several assistants and drillers advance in their own drilling careers.

During a cross-shift transition, Cazier and other Major Drilling experts examine safety aspects of a high wall near the drill site, making a list to discuss with the client, keeping crews happy and safe.

“He’s had supervisors who were his helpers back when he started drilling,” Fleming says. “Major Drilling is like a family, and Heath helps build it and make it stronger with every shift.”

Building the Major Drilling team is a big part of what makes drill supervision worthwhile to Cazier. Enthusiastically, he says, “It makes it feel like a Major Drilling family and a team where we build each other up. I feel like I’m not just a manager, I’m also a friend, a financial and relationship advisor, and sometimes even like a father to some drillers.”

When new drillers start work and may not be sure drilling is for them, Cazier takes time to drive the new hire around the site and teach them about how the work is done. He gives counsel about how to keep long hours from wearing a driller down and explains how important it is to get some checks in the bank before deciding on drilling as a career. “You either like it, or not,” he bluntly states.

Heath Cazier holds a rock veined with pyrite drilled in Long Canyon, Nevada in April 2015.

Cazier knows the best way to help his Major Drilling family is to guard against incidents in the field through safety training. “As a supervisor, it may seem like I’m supposed to know everything and have an answer to it all, but no one knows all the answers.”

He says that’s where TAKE 5, Major Drilling’s in-field risk assessment tool comes into play. He also implements and relies on the Critical Risks Management program and uses it and the 10 Lifesaving Rules during every shift as a simple, critical reminder for safety.

Quality is King

Today, even though ownership has changed hands, Cazier is back to work at the same project in Long Canyon where he started his drilling career in 2008. He works to keep client interactions transparent and positive. He adapts to each one as some are very businesslike, and others want to know fine details about how things are going.

Heath Cazier takes shelter during the first snowfall of the season while drilling at Kinsley Mountain, Nevada, in November 2014.

His cell phone has not stopped ringing all day. The excitement of being needed is the drive Cazier and his team need to keep their drill turning and get results. When asked if he’s happy with his career as a specialized drilling expert with Major Drilling, Cazier smiles and replies, “Pretty much. I only wish I would have started working with Major Drilling sooner.”

Follow Major Drilling on LinkedIn, Twitter, Facebook and Instagram to receive the latest company news and updates. Major Drilling celebrates 40 years of specialized drilling expertise from 1980-2020.

For information about Major Drilling careers, visit our Careers page.

Experience how partnering with Major Drilling leads to excellent results through experience, innovation, and safety. Learn more about how to make your next drilling project safe and successful with Major Drilling.