Major Drilling leaders in Salt Lake City, Utah, USA, recently unveiled new drills with specialized robotics and rod handling equipment for both surface and underground operations at two special innovation demonstrations for senior partners.

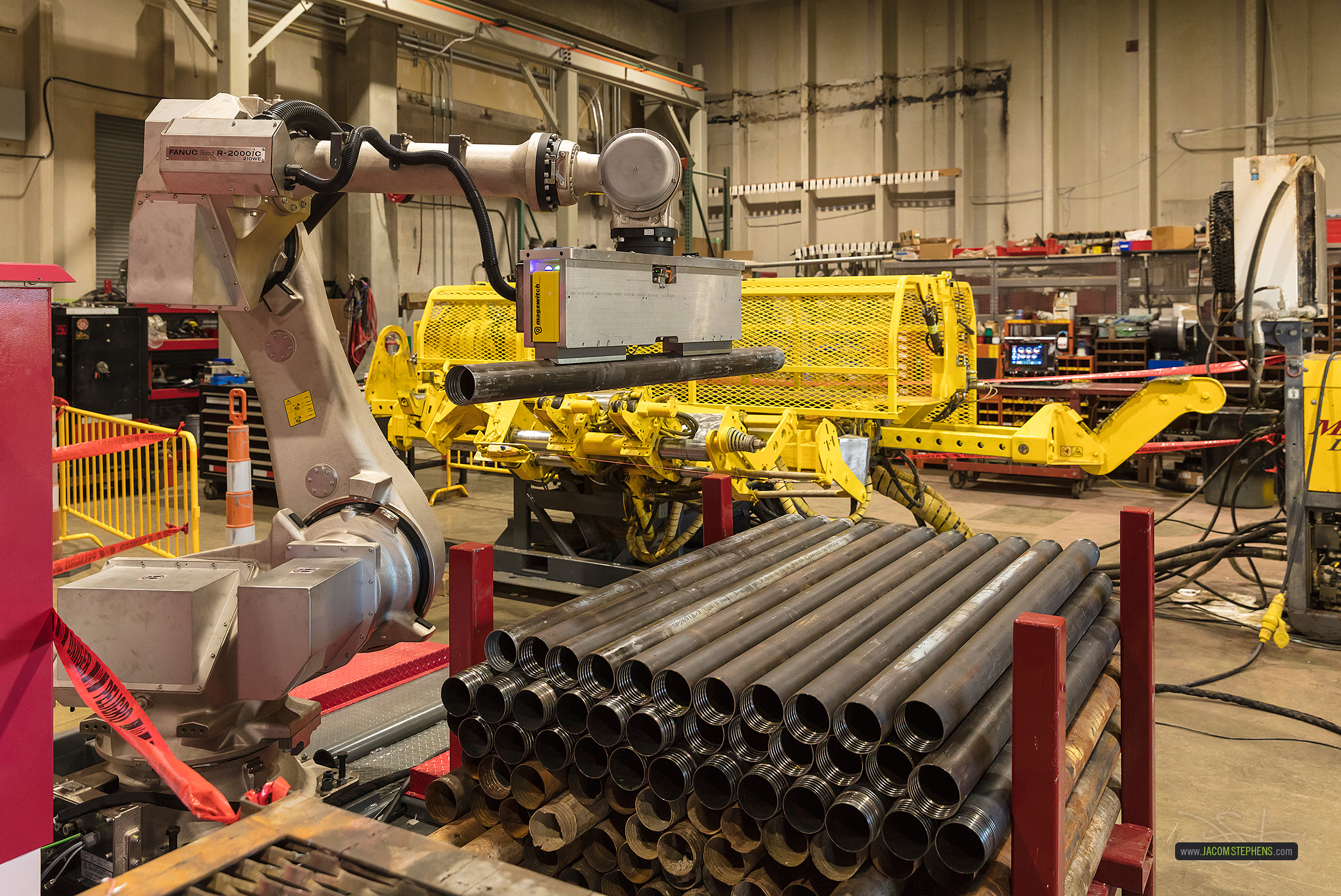

Guests assemble at the Major Drilling USA workshop to view a new high-powered magnetic hands-free robotic rod handler affixed to a Smart 8

underground drill.

A Smart 8 drill, already part of Major Drilling’s updated automated underground fleet, outfitted with a sleek robotic arm, used high-powered magnetic, hands-free technology to lift and load drill rods. Teams also displayed a mobile 6M underground core drilling rig equipped with a rod presenter.

The semi-autonomous rod handling robot, developed in Utah, addresses the growing need for hands-free rod handling while supporting Major Drilling’s safety initiatives. This versatile unit can be utilized across various underground drills. Being fully electric, it eliminates concerns about hydraulic leaks or repairs.

Innovating these semi-autonomous drilling solutions is an important part of the future of mining. Led by VP US Operations Kevin Slemko, the robotic arm was developed during early 2024. Deploying robotic rod handlers is one more indicator of Major Drilling’s embracement of emerging technologies to improve efficiencies for mining partners.

At an additional demonstration event, Major Drilling teams showcased the Apex 100 ultra-advanced RC mineral exploration rig with hands-free rod handling and the LF90 rod handlining conversion rig.

Customer expectations have always pushed Major Drilling to lead change and bring results. This is evident as senior mining partners regularly collaborate to test and give feedback on developing technologies which enhances not only their individual drill site but also Major Drilling’s overall performance.

“As a trusted mining supplier for our USA customers, we’re always looking for ways to give them innovative answers to their challenges,” Slemko said. “So, we’re very excited to demonstrate this new semi-autonomous robotic rod handling technology along with our Rock5 drill analytics because it truly shows how our solutions are making a difference in safety, productivity and efficiency.”

Data and the Future of Mining

Right now, the mining industry is abuzz about productivity and the future of data, prompting miners to press drilling contractors about how new tech is delivering these advantages to them. In answer, Major Drilling is developing a new innovative suite of services that is revolutionizing the use of artificial intelligence, survey tools and data analytics. Drillside GeoSolutions by Major Drilling combines the company’s traditional drilling services with borehole imaging by DGI Geoscience and automated core logging from KORE GeoSystems.

Addressing representatives from Rio Tinto and NGM, David Clarke (center), explains Major Drilling’s innovative path into the future of mining through TrailBlazer Rock5 drill data analytics as Christopher Klinger (right), technician responsible for installation of Rock5 consoles, looks on.

During one demonstration event, members of Major Drilling’s innovation team, David Clarke, Senior Advisor – Geological Technologies, and Christopher Klinger, Automation Technician, exhibited the complementary TrailBlazer Rock5 drill data analytics system and console being outfitted on drills fleetwide. Rock5 gathers real-time data that enhances drill team and customer safety, productivity and efficiency—a key part of Major Drilling’s suite of geosolutions delivered drillside with innovation partners DGI Geoscience Inc. and KORE Geosystems.

“It all starts with the Rock5 analytics,” Clarke said. “With our integrated data, imaging and automation solutions, we’re putting together a better geological model and better downstream benefits for all.”

Historically Innovative

Major Drilling teams showcase the Apex 100 RC rig (left) and the LF90 rod handling conversion rig with Freedom Loader.

In the last 10 years, Major Drilling has made great progress in technology around its drill sites and the tools it gives employees. The company is and has historically been a leader in drilling technology, helping customers build the mines of today and of the future.

Leadership teams from each branch around the world connect regularly to share their teams’ drillside innovation best practices that customers both expect and appreciate. With the acquisition of leading South American specialty driller Explomin Perforaciones, Major Drilling now moves into an era of growth opportunities in new jurisdictions, a diversified revenue source with additional underground operations, and an expanded senior customer base with high operational standards with 5,000 employees and over 700 drills.

Major Drilling prides itself on having the expertise necessary to meet the demands of global specialized drilling projects. The management team alone has more than 1,000 years of combined experience and uses their knowledge to guide the continuous improvement of drilling performance. That’s key to why Major Drilling is at the forefront of innovative solutions for the mining industry.

For more about Major Drilling’s innovation’s, visit GEOSOLUTIONS at majordrilling.com. Learn how partnership, leadership and cutting-edge technologies are combining to enhance customers’ safety, productivity and efficiency as the industry moves into the future

of mining.

Follow Major Drilling on LinkedIn, X, Facebook and Instagram to receive the latest company news and updates. Major Drilling Group International Inc. is the world’s leading provider of specialized drilling services primarily serving the mining industry. Established in 1980, Major Drilling has over 1,000 years of combined experience and expertise within its management team. The Company maintains field operations and offices in Canada, the United States, Mexico, South America, Asia, Africa, and Australia. Major Drilling provides a complete suite of drilling services including surface and underground coring, directional, reverse circulation, sonic, geotechnical, environmental, water-well, coal-bed methane, shallow gas, underground percussive/longhole drilling, surface drill and blast, a variety of mine services, and ongoing development of data-driven, high-tech drillside solutions.